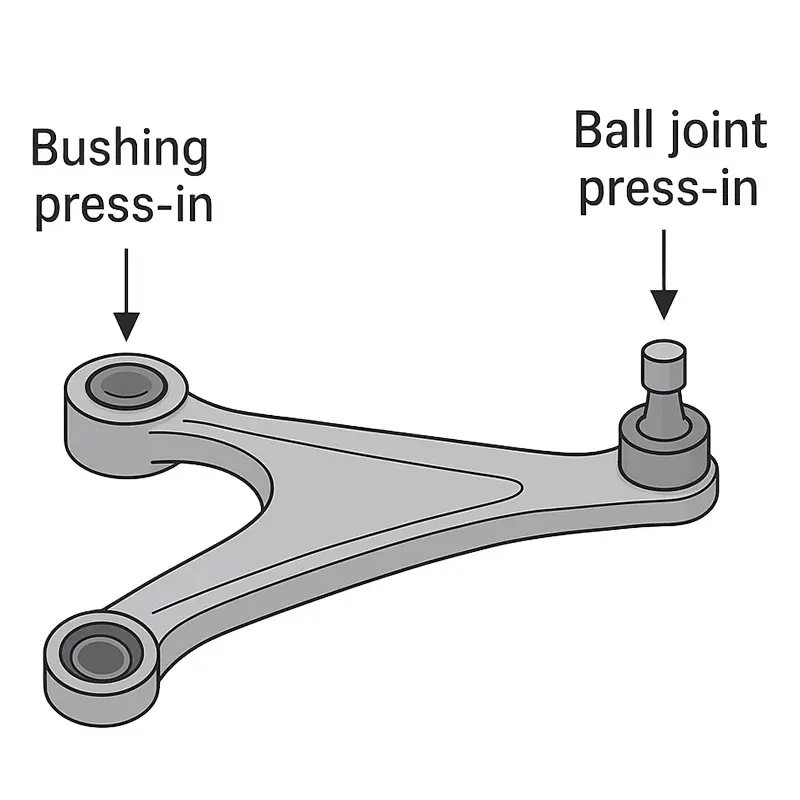

The automotive control arm is a critical component of the vehicle’s suspension system, connecting the chassis or subframe to the steering knuckle or wheel hub. It plays a vital role in load transmission, wheel motion guidance, and directly affects handling, ride comfort, and overall vehicle safety. Each control arm typically requires precision pressing of rubber or hydraulic bushings and ball joints at both ends. The assembly quality of these joints directly determines the NVH performance, stability, and service life of the entire vehicle. However, traditional hydraulic or pneumatic press machines struggle to achieve the precision, repeatability, and traceability demanded by modern automotive production. This article analyzes the pain points of conventional control arm assembly and demonstrates how XIRO electric servo press machines resolve these challenges through intelligent force, position, and speed control.

Automotive Control Arm Assembly

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

Ⅰ. Challenges in Traditional Control Arm Assembly

1. Bushing or Ball Joint Damage (Micro-Tearing, Wrinkling, or Deformation)

Pressing the bushing or sleeve requires precise force control. Excessive force causes deformation or internal tearing, while insufficient force leads to incomplete insertion or looseness.

Case: In a rear control arm durability test, rubber bushings failed prematurely due to micro-cracks in the inner rubber layer, caused by uncontrolled force peaks.

Root Causes:

Poor Pressure Control: Traditional hydraulic press machines have a control accuracy of ±5% FS or worse and slow response time. Instant pressure spikes can exceed material yield limits.

Improper Speed Control: Excessive pressing speed generates transient stress surges similar to a “water hammer effect,” causing internal stress concentration and micro-tears. Slow speed increases frictional heat and softens the rubber.

Misalignment: Axis deviation between the ram, bushing, and control arm bore leads to side-loading and uneven deformation. Traditional setups lack floating alignment or real-time compensation.

2. Insufficient Pressing Depth and Position Accuracy

Case: A front lower control arm ball stud required a flush tolerance of 0 ± 0.05 mm. Conventional presses resulted in +0.1 mm or –0.08 mm deviation, leading to interference or seal failure.

Causes:

Mechanical stops and limit switches offer limited accuracy (±0.1 mm) and drift with wear.

Hydraulic expansion and oil compressibility introduce thermal drift.

No real-time closed-loop control to adjust end position based on force feedback.

Tolerance stack-up of parts and fixtures not compensated in real time.

3. Lack of Process Visibility and Traceability

Traditional presses only display the final force value, offering no insight into the entire pressing process.

Issues:

Only endpoint parameters are monitored — the complete force-displacement curve is lost.

Process anomalies such as friction spikes, layer delamination, or yield plateaus cannot be detected.

No electronic data records, making SPC analysis and quality traceability impossible.

4. Inconsistent Interference Fit — Affecting Rigidity and Durability

Even within the same batch, variations in press parameters cause differences in contact stress and residual strain, leading to NVH inconsistencies and premature fatigue.

Causes:

Inaccurate pressure control leads to variable interference and contact stress.

Pressing speed affects friction behavior and viscoelastic properties of rubber.

Uneven residual stress distribution reduces fatigue trength near weld zones.

5. Low Changeover Efficiency and Error-Prone Parameter Adjustment

Case: During mixed-model production, an operator failed to reset the mechanical stop after product changeover, resulting in a batch of control arms with excessive bushing insertion depth.

Causes:

Mechanical adjustments and fixture changes are time-consuming and error-prone.

Press parameters (force, speed, position) rely heavily on operator experience and trial-and-error.

No centralized recipe management for quick and error-free model switching.

Ⅱ. Key Technologies of XIRO Electric Servo Press Machine

1. Eliminating Damage and Ensuring Consistent Interference Fit — Precision Force/Position/Speed Control

1.1 High-Performance Servo Drive and Closed-Loop Control

Force Control Accuracy: ±0.5% F.S., nearly 10× higher precision than traditional hydraulic presses.

Position Accuracy: ±0.01 mm via high-resolution encoder or linear scale.

Multi-stage Speed Control: Approach, press, hold, and return speeds are programmable to prevent stress spikes and control heat buildup.

Soft Landing: Acceleration control enables smooth contact, avoiding impact deformation.

1.2 Real-Time Force–Displacement Curve Monitoring

The system captures and records the complete pressing curve in milliseconds.

Each cycle is compared to a pre-defined "OK window"tolerance band for automatic judgment.

Ensures consistent interference fit and residual stress distribution across all products.

2. Ensuring Pressing Depth Accuracy — Absolute Position Control and Compensation Algorithms

Linear scale feedback provides absolute position reference independent of mechanical drift.

Hybrid force-position control automatically stops when the target force is achieved within the position window.

Real-time temperature and elastic deformation compensation guarantees long-term stability.

XIRO Electric Servo Press (Customizable )

3. Full Process Traceability and Intelligent Data Analytics

Comprehensive Data Logging: Each cycle records timestamp, force-displacement curve, set parameters, and product ID (via barcode).

SPC Statistical Control: Calculates CPK for key parameters (max force, end force, displacement, curve area, etc.).

MES/QMS Integration: Data can be uploaded through OPC UA or TCP/IP protocols for remote quality management.

Curve Comparison and AI Diagnostics: Optional AI pattern recognition detects tooling wear or early process drift.

4. Streamlined Changeover and Parameterized Program Management

Recipe Management: Each control arm model or pressing point stores a complete parameter set (target curve, speed stages, hold time, tolerance bands, safety limits).

One-Touch Changeover: Operators select the product model via HMI, and the system automatically loads all relevant settings — eliminating manual errors and reducing downtime.

Conclusion

XIRO electric servo press machine revolutionizes automotive control arm assembly through precise closed-loop force, position, and speed control, real-time process visualization, and full data traceability.

It fundamentally solves issues such as bushing damage, positional deviation, inconsistent interference fit, and inefficient model switching.

By adopting a servo pressing system, manufacturers achieve higher assembly consistency, longer product lifespan, and smarter production lines — meeting the strict quality standards of modern automotive suspension systems.