Nut pressing is a critical assembly process that directly impacts the mechanical reliability and service life of structural connections. Traditional hydraulic and pneumatic press machines suffer from systemic limitations in precision control, energy efficiency, and production adaptability. In contrast, electric servo press machines—enabled by closed-loop force-displacement control and digital process management—have achieved a significant leap in performance.

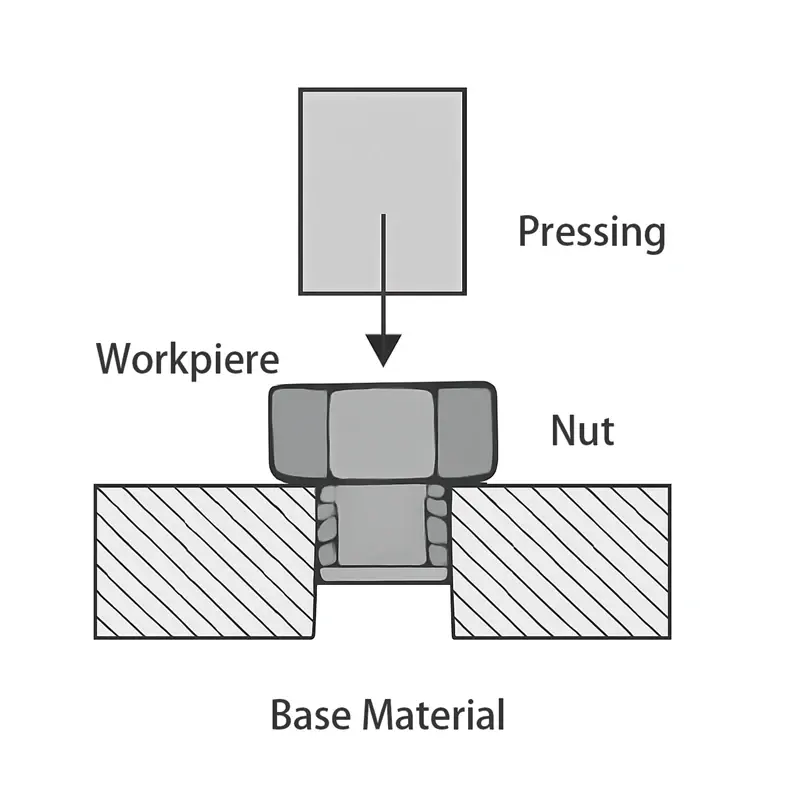

Precision Nut Pressing Process

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

1. Inconsistent Pressing Force Leading to Fretting Wear

Case Study: In a new energy vehicle (NEV) project, steering knuckle nuts became loose due to a subcontractor failing to meet the specified torque requirement of 98 ± 10 N·m. Positioned at the end of the rear suspension's lateral control arm, these loose nuts caused a 300% spike in tire wear, triggering a recall of over 200 vehicles.

Root Cause Analysis:

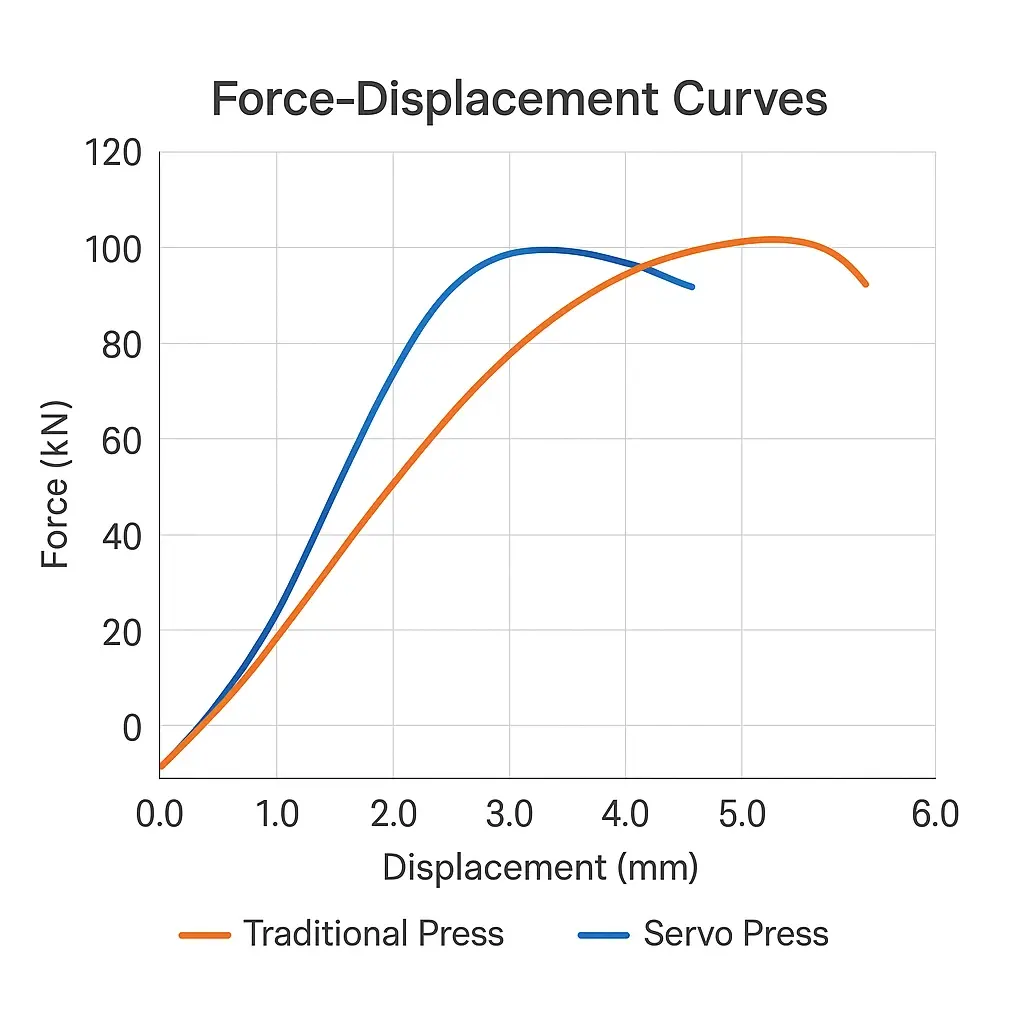

Traditional open-loop press systems show pressing force fluctuation of ±15% Full Scale (FS), with actual values ranging from 102–138 kN (for a 120 kN target).

Over 30% of nuts fell below the designed preload range of 85–115 kN.

The coefficient of variation (CV) for preload measured at 0.28, significantly exceeding the industry benchmark (CV ≤ 0.1), resulting in uneven thread contact stress.

Scanning Electron Microscopy (SEM) revealed characteristic Fe₃O₄ debris in the contact area, confirming oxidation-driven fretting fatigue.

Measured micro-slip exceeded 125 μm—well above the critical fretting threshold of 100 μm—leading to oxide layer spalling and surface fatigue.

XIRO Electric Servo Press Solution:

Dual closed-loop control for force and displacement achieves ±0.5% FS force precision, with a response time of 5 ms.

Initial contact detection uses a current surge trigger (±2 N sensitivity) to precisely identify contact initiation.

"Force-priority" mode ensures final compression with ±0.05 mm displacement tolerance.

Dynamic PID-based torque compensation adjusts the servo motor every 4 ms for consistent output.

Measured Results:

Preload CV improved from 0.28 to 0.03.

Force accuracy enhanced to ±1.5% FS.

Nut press consistency and structural reliability significantly improved.

2. Material Mismatch Causing Nut Cracking

Case Study: In an NEV battery pack, aluminum housing (6061-T6) experienced batch-level nut cracking during press-fit operations. Cracks radiated outward from the nut interface, with microcracks up to 50 μm along a 45° angle from the thread root.

Root Cause Analysis:

Fixed-speed hydraulic presses (20 mm/s) lack adaptive strain rate control.

Measured plastic deformation was only 38%—far below the ≥60% design target—resulting in residual stress concentration with a stress factor Kt of 2.1.

With a material strain-rate sensitivity of δ = 0.015, local strain exceeded the 0.1/s threshold, increasing hardness by 15% and raising crack risk by 47%.

XIRO Electric Servo Press Solution:

Multi-stage variable-speed press profile with intelligent force feedback:

Low-speed positioning (0.5 mm/s): Eliminates gaps and avoids impact.

Constant strain-rate extrusion (3 mm/s): Ensures optimal material flow.

Pulse feed compensation (0.1 mm/s): Offsets elastic recovery and minimizes residual stress.

Measured Results:

Nut cracking rate reduced from 12.3% to 0.4%.

Metallographic analysis confirmed grain flow alignment and structural integrity.

Force Displacement Curves Of Precision Nut Pressing

(Data source:XIRO)

3. Poor Process Adaptability in Multi-Spec Nut Production

Case Study: An aerospace fastener plant encountered major productivity losses in M5–M12 nut mixed-line production. Manual changeovers involving 12–15 limiters took over 25 minutes each. Four changeovers per day led to 100+ minutes of downtime, and the first-pass yield was just 82%.

Root Cause Analysis:

Manual adjustments for mechanical stops were time-consuming and error-prone.

Hydraulic valve latency (80–120 ms) caused force fluctuations of ±15%, exceeding the ±5% specification range.

Oil viscosity dropped at 60°C, increasing internal leakage by 40% and destabilizing pressure output.

XIRO Electric Servo Press Solution:

Smart positioning system: A 6-axis robotic arm achieves ±0.1 mm positioning accuracy, eliminating mechanical stops.

Rapid changeover system: HMI one-touch switching combined with RFID model recognition auto-loads the correct pressing recipe.

Fully servo-driven architecture: Programmed speed control (0.1–50 mm/s) with zero hydraulic lag.

Measured Results:

Changeover time reduced from 25 minutes to under 30 seconds.

First-pass yield rose from 82% to 99.2%.

Supports over 100 programmable nut press parameters for flexible production.

Conclusion

XIRO electric servo press machines offer a transformative solution for precision nut pressing applications. By addressing common pain points—such as force inconsistency, cracking risk, and process inflexibility—these systems enable digital control, predictive accuracy, and rapid scalability. Especially in automotive, aerospace, and battery housing industries, servo-controlled press machines ensure higher assembly quality, reduced defect rates, and lower total cost of ownership.For manufacturers aiming to modernize their press systems and achieve Industry 4.0 standards, XIRO servo press solutions represent a future-proof investment in both performance and productivity.

Discover how XIRO Electric servo press technology can help your production line reduce scrap, accelerate changeovers, and improve traceability. Contact us or visit YouTube channel to explore 100+ servo press applications demos across the automotive, aerospace, and precision manufacturing sectors.