In the era of high power density development in new energy vehicle (NEV) motors, the water-cooled spindle, as the core component for heat dissipation, directly determines the efficiency, service life, and reliability of the motor. The quality of spindle press-fitting is therefore critical. Traditional hydraulic press machines and pneumatic press machines face challenges such as uncontrolled pressure, positional deviation, and lack of data traceability. These challenges are now being resolved through the mechatronic intelligence of the electric servo press machine.

This article provides a detailed analysis of how XIRO electric servo press technology ensures the precision, quality, and traceability of electric motor assembly.

Water-Cooled Spindle

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

I. Challenges of Traditional Press-Fitting Methods

Challenges 1: Insufficient Pressure Control Accuracy Leading to Bearing Overload Damage

Case Study:A NEV motor manufacturer used a 200-ton hydraulic press machine to assemble water-cooled spindles with double-row angular contact bearings. Nearly 30% of finished spindles exhibited 800Hz high-frequency noise during bench testing. Disassembly revealed Brinell indentations (0.3–0.5mm) on the bearing raceways, and spindle radial runout exceeded 0.012mm (specification ≤0.005mm).

Failure Analysis:

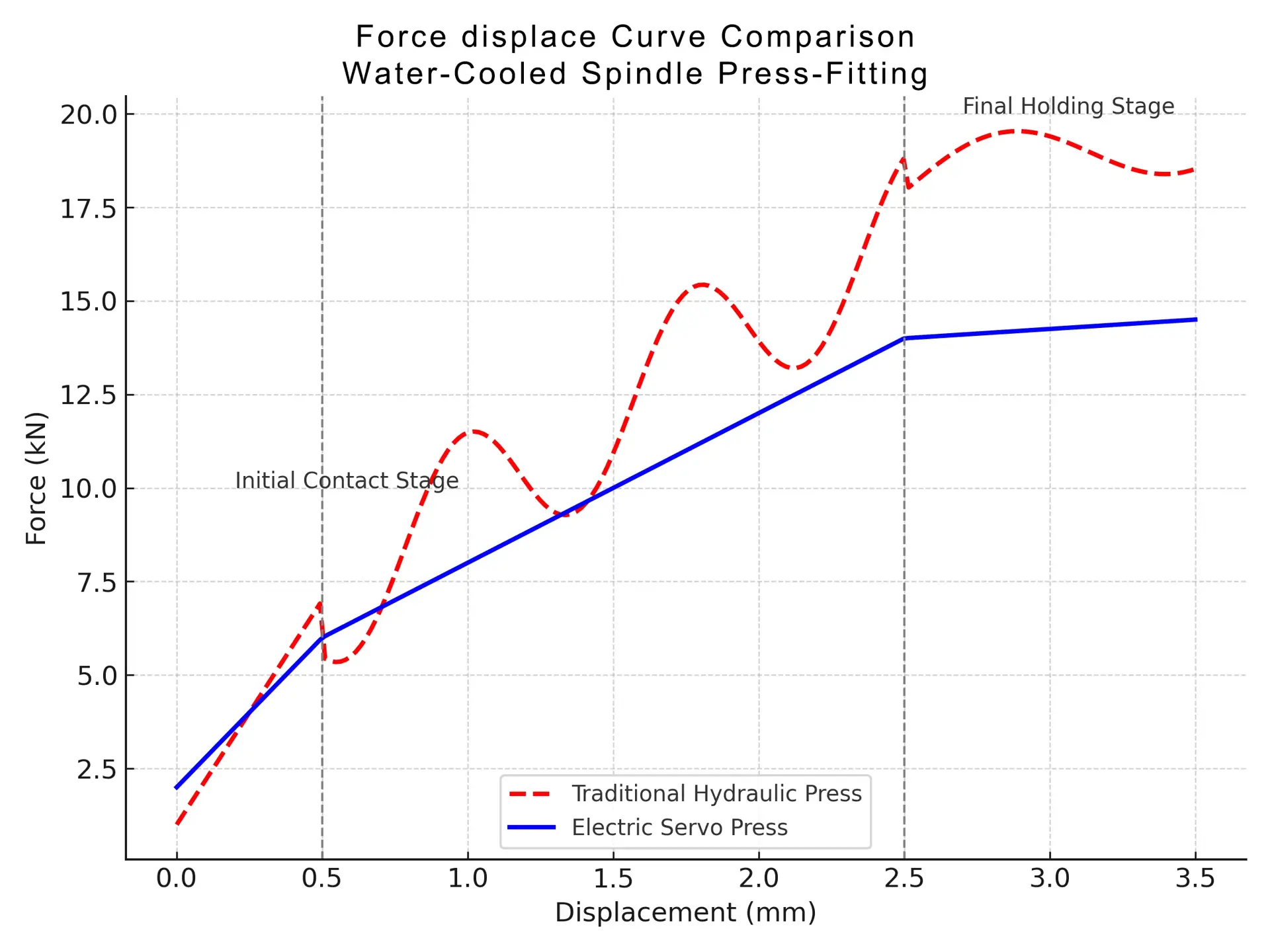

1. Hydraulic system lag: Slow response time (>200ms). When the bearing sleeve entered the interference fit section (2.1mm press depth), the system failed to react to load spikes. Peak force reached 20.7kN (15% above design value), exceeding the bearing steel yield limit.

2. Relief valve precision limitation: Control error ±8% F.S., exceeding the safe press-fitting window.

3. Thermal drift of hydraulic oil: Oil temperature increase from 40℃ to 60℃ caused pressure deviation to rise from ±3% to ±12%, tripling the overpressure risk.

Challenges 2: Position Control Failure Causing Seal Ring Shear and Leakage

Case Study: A high-end motor manufacturer used an 80-ton pneumatic press machine to assemble water-cooled spindle end covers (A356 aluminum). During water pressure testing (2.0MPa/30min), leakage rate reached 12%. Failure analysis revealed that 68% of defective parts had seal rings sheared (cross-section deformation >40%), with visible metal burr scratches of 20–50μm.

Failure Analysis:

1. Friction fluctuation (Stribeck effect): Caused ±0.085mm positional deviation when O-ring entered the groove at low speed (<5mm .="" resulted="" in="" 0.35mm="" one-sided="" extrusion="">15% of groove width).

*Test Data:

| Phase | Speed | Friction | Position deviation |

| Start phase | 0→3mm/s | 420±150N | ±85μm |

| Constant speed | 40mm/s | 180±40N | ±25μm |

| End phase | 40→0mm/s | -90~+310N | ±110μm |

2. Mechanical stopper wear: 0.15mm accumulated wear reduced end position from 2.85mm to 2.70mm, increasing O-ring compression from 18% to 23% (above FKM limit of 20%).

3. Open-loop control limitations: Positioning by magnetic switch (accuracy ±0.5mm), no real-time feedback. Caused assembly tilt and uneven interference.

Challenges 3: Lack of Process Data Prevents Quality Traceability

Case Study: One motor manufacturer experienced 12% spindle coolant leakage within six months of service, leading to a full batch recall. Analysis showed:

-

58% bearing outer rings creeping (>0.5mm axial displacement)

-

32% seal face microcracks (>3mm length)

-

10% bearing raceway spalling (>2mm² area)

Failure Analysis:

-

Traditional press machines lacked data collection, relying on manual sampling with high miss rates.

-

No record of key parameters (peak force, press depth, dwell time, press speed, force-displacement curve), making root cause identification difficult.

*Examples:

| Failure | Possible reason 1: Assembly issue | Possible reason 2: Parts issue |

| Bearing outer ring creep | Insufficient press force (≤14kN) | Undersized shaft diameter (≤φ79.995mm) |

| Seal face cracks | Tilted press (>0.5°) | Excessive seal hardness (>85SHA) |

| Raceway spalling | Shock loading (jerk >200m/s³) | Low steel purity |

II. XIRO Electric Servo Press Machine Solutions

1. High-Dynamic Closed-Loop Force Control (Eliminating Overload Damage)

-

Strain-gauge force sensor (±0.25% F.S.) + servo motor torque control (response<5ms).

-

PID adaptive algorithm (fluctuation <±1%) ensures constant press force.

-

Dynamic force limiting at interference point prevents Brinell indentation.

2. Real-Time Thermal Drift Compensation

Built-in temperature sensor (±0.1℃), force-temperature compensation model ensures stable force accuracy.

*Test results:

| Temperature changes | Hydraulic press | Electric servo press |

| At +10℃ | Deviation +8% | +0.12% |

| At +20℃ | Deviation +15% | +0.25% |

3. Precision Position Servo System (Preventing Seal Damage)

-

3D force sensor + high-resolution linear encoder for closed-loop control, repeatability ±0.01mm.

-

Three-stage velocity profile: deceleration to 2mm/s near groove, soft pressing ensures O-ring integrity.

*Test comparison:

| Item | Pneumatic press | Electric servo press |

| Positioning Repeatability | ±0.1mm | ±0.01mm |

| Leakage rate | 12% | 0.15% |

| O-ring damage rate | 8.7% | 0.02% |

Force-Displacement Curve Comparison: Pneumatic vs Electric Servo Press

(Source: XIRO )

4. Full Process Data Collection and Traceability

1. High-precision sensor network:

-

Linear encoder records displacement trajectory.

-

Torque sensor monitors real-time press force.

-

Temperature sensor records contact temperature.

2. Digital force-displacement curve analysis:

-

Identifies interference point, pressure gradient, synchronization errors.

-

Online defect judgment (e.g., force deviation >8% in X/Y indicates tilt).

3. Data connectivity:

-

Automatic MES upload.

-

Supports Industrial Ethernet & OPC UA for smart manufacturing integration.

Conclusion

XIRO electric servo press machine resolves three major challenges of traditional hydraulic and pneumatic press machines in NEV water-cooled spindle assembly: overpressure damage, positional deviation, and lack of process data.

Compared with conventional assembly machines, XIRO electric servo press technology significantly reduces bearing damage and leakage rates, ensuring high precision and consistency in spindle press-fitting. Moreover, its digitalization, full traceability, and smart manufacturing integration provide robust process assurance for the high power density, extended service life, and reliability of new energy vehicle motors.

Discover how XIRO Electric servo press technology can help your production line reduce scrap, accelerate changeovers, and improve traceability. Contact us or visit YouTube channel to explore 100+ servo press applications demos across the automotive, aerospace, and precision manufacturing sectors.