Introduction

Electronic oil pumps serve as a key component in thermal management for new energy vehicles, start-stop systems in internal combustion engines, and hydraulic control in transmissions. Their assembly quality directly impacts vehicle performance and safety. With advantages such as high precision, digital control, and clean operation, electric servo press machines have become a critical technology in the intelligent assembly of automotive oil pump systems.

1. Key Process Requirements in Electronic Oil Pump Assembly

Precision Press-Fit Requirements

Rotor-to-stator interference fit: Tolerance typically < 0.01 mm

Bearing/sleeve press-fit: Requires extremely accurate force control

Plastic-to-metal component fitting: Must avoid housing deformation

2. In-Process Quality Control

Seal ring press-fit consistency: Critical to leakage testing outcomes

Magnet cleanliness: Prevent metallic debris contamination during motor assembly

Electronic Oil Pump

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

Ⅰ Industry Case Studies – Traditional Challenges

With growing performance requirements in new energy vehicle hydraulic systems, conventional press machines often fail to meet the precision and traceability demands of oil pump assembly.

Case 1: Poor Interference Fit Leads to Motor Casing Scoring

A hybrid vehicle model reported a 3.2% failure rate in electronic oil pumps. Disassembly revealed scoring inside the stator housing.

Root causes included:

Surface roughness above 0.8μm: Breaks lubricant film continuity, increasing boundary friction

Non-uniform plastic deformation: Creates residual stress gradients at the rotor-shaft interface, resulting in dynamic eccentricity > 0.03 mm at speeds over 8000 rpm

Stator ovality: Radial press force >15 MPa causes plastic deformation in aluminum housing. Roundness deviation > 0.1 mm reduces O-ring compression from 25% to<15%, leading to hydraulic leakage

Case 2: Ceramic Bearing Fracture Due to Brittle Failure

In an 800V hybrid transmission oil pump line, a Japanese OEM reported a 4.7% ceramic bearing breakage rate.

Failure analysis showed 82% of fractures occurred as radial cracks in the inner ring. Press-fit process data showed:

| Parameter | Standard | Actual | Deviation |

| Peak pressing force | ≤22 kN | 26.8 kN | 1.22× |

| Force ramp-up rate | ≤0.5 kN/ms | 1.2 kN/ms | 2.4× |

| Punch alignment offset | ≤0.02 mm | 0.08 mm | 4× |

Conclusion: Traditional press machines cannot effectively suppress overshoot (instant pressure spikes up to 130%), nor can they maintain alignment, which is critical when pressing brittle materials like ceramics (fracture threshold < 22 kN).

Case 3: Particle Contamination Leading to Leakage and Short Circuits

A new energy vehicle motor assembly line suffered 0.7% monthly rejection rate due to copper particle-induced electrical shorts.

Contaminants originated from:

Copper sleeve scratches

Housing burrs

Friction between punch and housing

| Parameter | Standard | Measured | Failure Mechanism |

| Pressing Force | 80 kN | 120 kN | Exceeded material yield |

| Pressing Speed | 2 mm/s | 5 mm/s | Caused high-impact debris |

Ⅱ XIRO Electric Servo Press Machine – Smart Solutions in Action

In precision assembly of electronic oil and fuel pumps, XIRO servo press machines provide reliable solutions for rotor-shaft fits, ceramic bearing pressing, and stator core housing insertion.

1. Rotor-to-Shaft Press-Fit (Interference Fit)

Dual Closed-Loop Control (Force + Displacement)

Detection Stage: Low-pressure alignment, compensates ±0.1 mm positional error

Pressing Stage: Speed at 0.5 mm/s to limit material distortion

End Compensation: 0–15μm displacement to offset elastic rebound

Real-time pressure gradient monitoring (dP/dS) triggers alarm for deviations ±15%.

| Parameter | Control Target | Failure Risk | XIRO |

| Interference Fit | 5–15 μm (per shaft size) | Rotor imbalance | Micro-rebound compensation (2μm) |

| Press Speed | 0.3–0.8 mm/s | Copper sleeve damage | S-curve speed profile to suppress impact |

| Force Monitoring | Peak ±3% | Shaft microcracks | Gradient alarm (dF/ds > 5 kN/mm) halt |

3. Ceramic Bearing Press-Fit (High-Speed Support Element)

Pressure-Position Hybrid Control

Force Limiting: Ensures stress < 30% of ceramic’s flexural strength

μs-Level Pressure Sensor: 50 kHz sampling captures and blocks >8 kN impact loads in<0.1 ms

High-resolution encoder (grating scale): Position accuracy ±2 μm (vs. ±15 μm in traditional setups)

| Metric | Traditional | XIRO |

| Ceramic Breakage Rate | 1.8% | 0.03% |

| Position Accuracy | ±15 μm | ±3 μm |

| Cycle Time | 22 sec/pc | 18 sec/pc |

| Process Capability (CPK) | 1.12 | 1.87 |

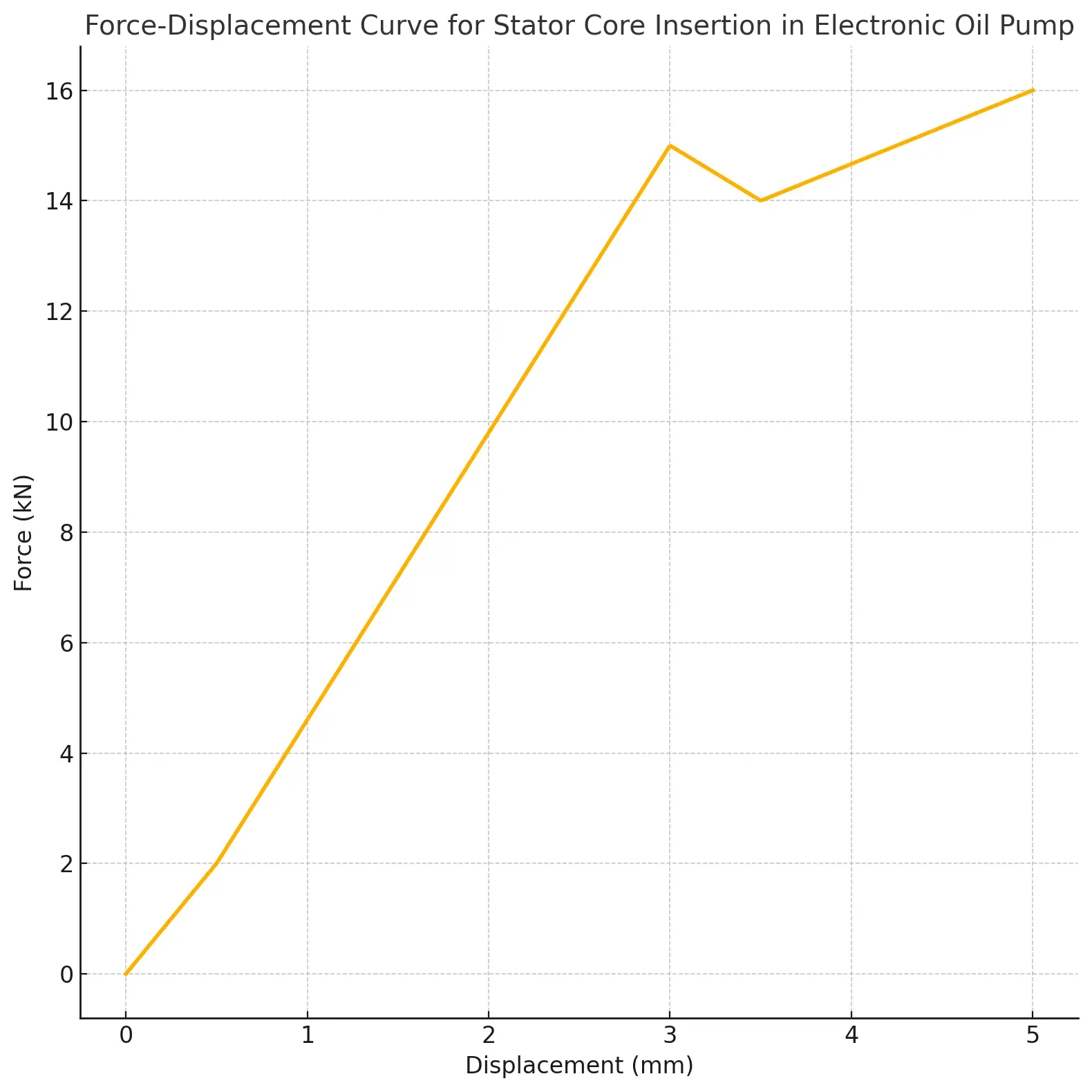

Force-position curve of electric oil pump

(Source: XIRO )

3. Stator Core Insertion into Housing (EM Component Assembly)

Key Features:

Multi-Axis Synchronization: Independent servo axes (±0.005 mm) for uniform pressure distribution

Multi-Stage Pressing: Pre-press → Main press → Dwell, to control deformation (ellipticity ≤ 0.02 mm)

Thermal Compensation: Housing pre-heated to 120 ± 3℃. Real-time IR sensing dynamically adjusts press-fit parameters to optimize residual stress

| Challenge | XIRO Solution | Quality Target |

| Thin-wall deformation | Multi-stage pressure control | Post-fit roundness ≤ 0.05 mm |

| Coil insulation damage | Press speed ≤ 1 mm/s | Dielectric test >1500V AC |

| Lamination looseness | 200Hz vibration @ 5μm | No-load current fluctuation<5% |

Conclusion

XIRO electric servo press machines offer a precision assembly platform tailored for next-generation automotive components. By eliminating traditional challenges such as interference fit errors, ceramic bearing breakage, and contamination-induced failures, XIRO delivers measurable improvements in product consistency, reliability, and process traceability. These intelligent press machines are rapidly becoming the backbone of smart manufacturing in the EV era.

Discover how XIRO Electric servo press technology can help your production line reduce scrap, accelerate changeovers, and improve traceability. Contact us or visit YouTube channel to explore 100+ servo press applications demos across the automotive, aerospace, and precision manufacturing sectors.