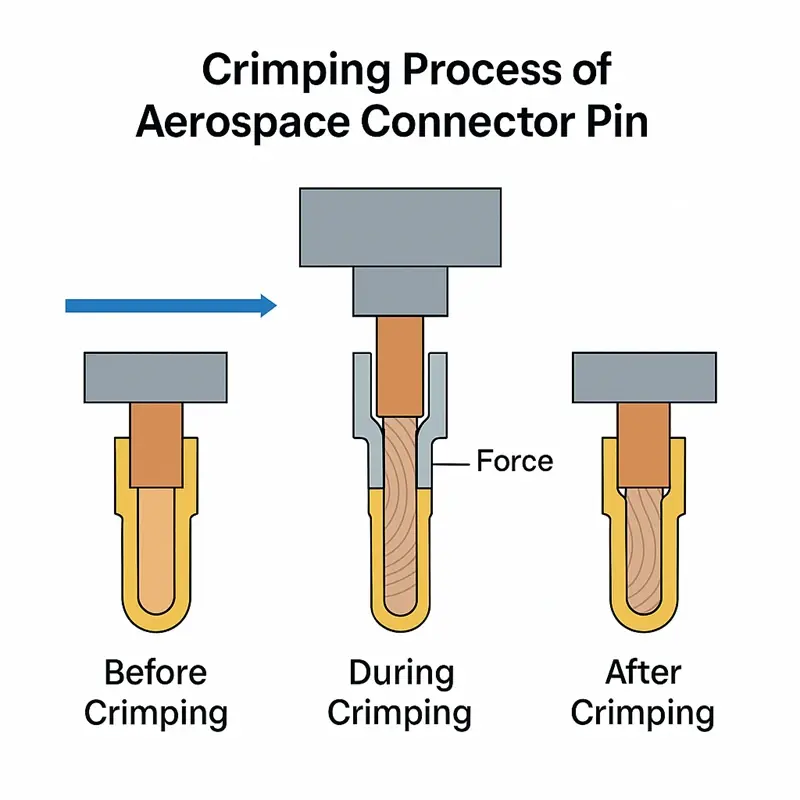

Aerospace connector pins are critical conductive nodes in the electrical systems of aircraft and spacecraft. Their crimping quality directly affects the overall safety and long-term reliability of the system. The crimping of aerospace connector pins is a process that achieves the connection between metal pins and wires through plastic deformation. It is a metal plastic deformation connection method that does not involve heat sources (as opposed to welding) and relies on precise pressure control to achieve interference fit. This article explores the challenges of pin crimping technology in aerospace connectors pins through case studies, and provides an in-depth analysis of the precise control capabilities of XIRO electric servo press.

Crimping Process of Aerospace Connector Pins

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

ⅠCommon Crimping Challenges and Case Studies

1. Crimp Height Deviation Leading to Poor Contact

Case: A certain UAV experienced intermittent signal transmission due to a pin crimping height deviation of ±0.15mm, which exceeded the tolerance of ±0.1mm.

Analysis: Traditional hydraulic press machines struggle with micron-level control, often resulting in:

Over-crimping: Force exceeds the yield strength of phosphor bronze, causing microcracks in pins and increasing contact resistance by 40%.

Under-crimping: Incomplete compaction of the conductor core leads to internal voids, reducing current-carrying capacity by up to 50%.

Failure Mechanism: In vibration environments, these imperfections create micro-arcs that burn through the 0.76μm gold plating, resulting in signal loss.

Solution: Use XIRO electric servo press with real-time pressure-displacement curve monitoring. The system can detect when optimal contact is achieved and terminate the press cycle, avoiding both over- and under-compression.

2. Pin Misalignment Causing Stress Concentration

Case: A spacecraft connector failed due to a 5° tilt of the crimped pin, leading to arc damage during flight vibrations.

Analysis:

Stress Concentration: Misalignment increased localized stress by 300%, far exceeding the yield limit of phosphor bronze.

Arc Formation: Vibration-induced resistance fluctuations triggered intermittent discharge, heating the contact point to 4000°C.

Failure Mode: Microcracks propagate under stress, ultimately causing full detachment at the contact surface.

Solution: XIRO electric servo press, equipped with high-precision guide rails and optical linear scales (±0.01mm accuracy), ensures that crimping is precisely aligned. Optionally, vision-guided systems can further reduce angular deviation to below ±0.5°.

3. Coating Damage Causing Signal Attenuation

Case: In an airborne radar, high-frequency connector pins suffered gold plating damage due to crimp friction, increasing signal loss by 37%.

Analysis:

Impact-style crimping generates excessive friction:

Damage Mechanism: Instantaneous friction forces >50N caused microcracks over 20μm long on the 0.76μm gold plating.

Signal Loss: Increased current density at damaged areas—combined with the skin effect—raised signal loss by 37%.

Outcome: VSWR at >10GHz worsened to 1.8, reducing radar detection range by 22%.

Solution: XIRO electric servo press uses nano-diamond coated molds and low-speed compression (<5mm/s), reducing coating damage rate to as low as 0.3%.

4. Loose Multi-Stranded Conductors Reducing Current-Carrying Capacity

Case: A high-voltage harness in an electric aircraft experienced a 165°C temperature rise during operation due to poor core fill, triggering fire.

Analysis:

Structural Defect: Core fill rate only 85% (vs. aviation standard ≥90%), reducing conductive area by 30%.

Thermal Runaway: Loose wires increased contact resistance by 50%, generating Joule heat and causing localized overheating (65°C over limit).

Failure Chain:

Oxidized wire → poor contact → micro-arcing → insulation carbonization → short circuit and fire

Solution: The servo-controlled crimping process uses 3-axis pressure modulation and pulsating force (±2%Fmax at 50Hz), enabling uniform wire compaction. Result: a more reliable, flame-resistant crimping structure.

Ⅱ XIRO Electric Servo Press Machine Solution

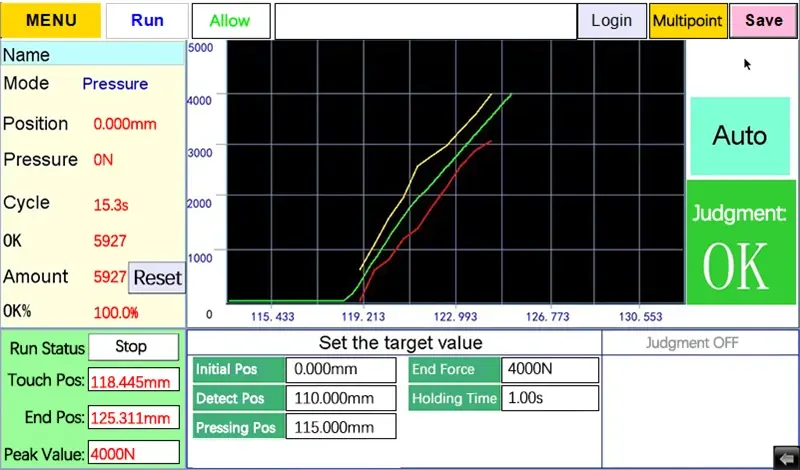

1. Closed-Loop Pressure-Displacement Control

Utilizes ±0.5%FS pressure sensors and 0.001mm resolution encoders.

Ensures precise three-phase crimping curve:

Pre-press: 10–30% Fmax to eliminate gaps

Main press: 70–90% Fmax for plastic deformation

Dwell hold: ~5% Fmax for >50ms microstructure stabilization

Closed-loop control with linear optical encoders ensures repeatable positioning accuracy of ±0.01mm.

XIRO Electric Servo Press Pressure-Position Curve Monitoring Interface

2. High Rigidity and Anti-Vibration Structure

Precision ball screw (lead error ≤5μm/100mm) with reinforced linear guide rails maintains stability under vibration.

Machine frame uses cast iron or welded steel with stiffness ≥200GPa, deformation<0.02mm/m under load.

Result: Crimp angle fluctuation is controlled within ±0.5°.

3. Multi-Axis Pulsating Crimping Control

Based on force feedback pulsation (±2%Fmax at 50Hz)

Enables X/Y/Z axis modulation with ±0.01mm precision

Uniform compaction of multi-strand wires ensures superior fill rate

Additional Specs:

Crimping Speed: 1.5 mm/s (variable)

Terminal Pressure: Cross-section × 70 MPa

Hold Time: 300ms ±10ms

Conclusion

XIRO electric servo press machine introduces a paradigm shift in the precision crimping of aerospace connector pins. Through closed-loop control, micron-level positioning, and programmable press profiles, it ensures optimal crimp integrity and reliability. The system automatically monitors real-time pressure-displacement curves, ending the cycle once the deformation enters the ideal plastic zone, avoiding microcracks and coating damage. Its multi-segment crimp profiles—featuring slow-speed pre-contact, precision pressing, and anti-tilt alignment—make it ideal for high-mix, high-reliability production environments in aerospace, military, and high-frequency communications.

Discover how XIRO Electric servo press technology can help your production line reduce scrap, accelerate changeovers, and improve traceability. Contact us or visit YouTube channel to explore 100+ servo press applications demos across the automotive, aerospace, and precision manufacturing sectors.