In automotive manufacturing, the quality of frame sleeve assembly directly determines the vehicle’s load-bearing capability and fatigue life. Traditional manual assembly or hydraulic press methods often suffer from low accuracy, poor consistency, and a lack of process data transparency—becoming a major bottleneck in quality improvement.

As an experienced manufacturer in industrial automation, XIRO integrates visual guidance, servo control, and data traceability technologies to provide a fully automated and intelligent

frame sleeve pressing solution. This solution ensures stable precision, high efficiency, and complete process visibility throughout the entire sleeve pressing operation.

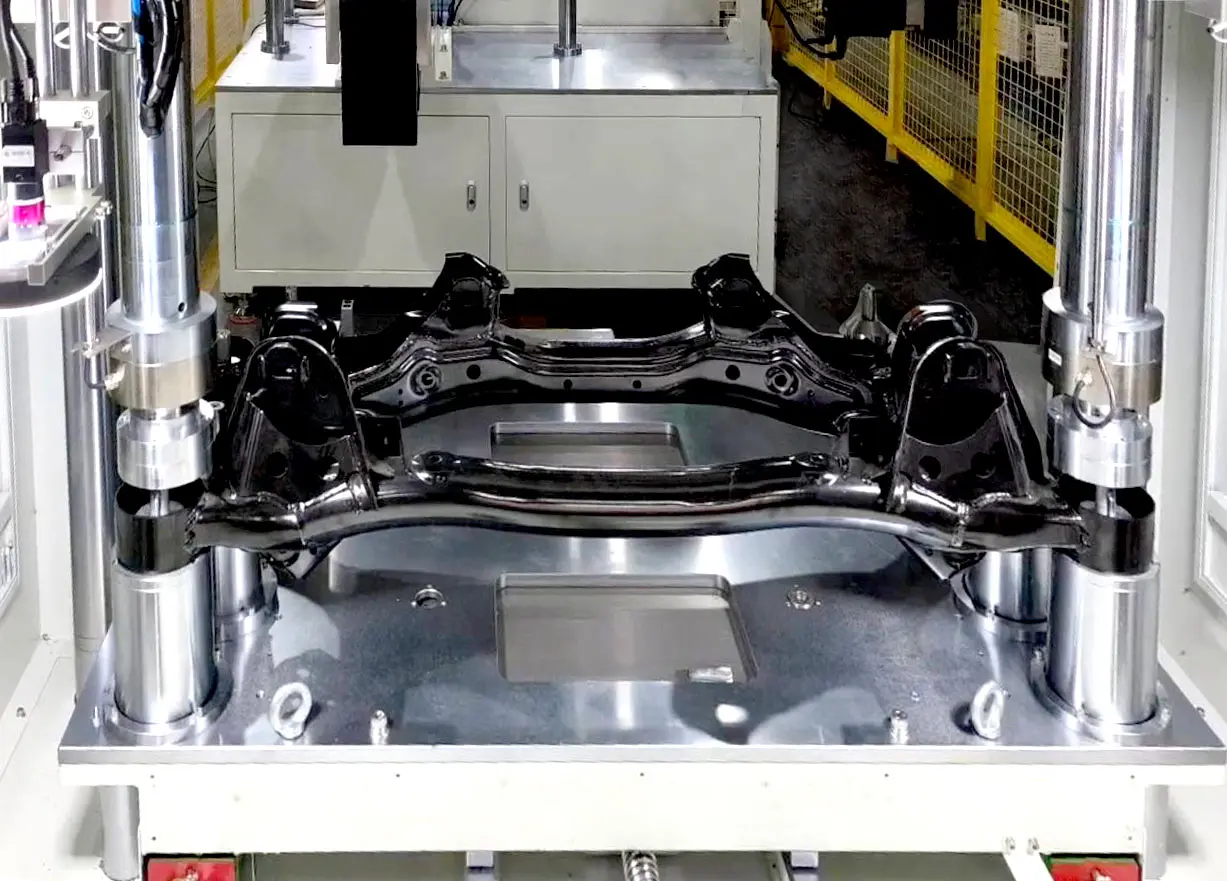

Automotive Frame Sleeve

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

1. Automated Loading and Visual Compensation Positioning

(1) Automated Loading and Unloading

The XIRO system uses a servo-motor-driven transfer unit to automatically convey workpieces to and from the designated pressing position. Programmable stroke and speed control, along with sensor feedback and closed-loop monitoring, minimize human intervention, reduce handling time, and improve operational safety and equipment reliability.

(2) Vision-Guided Positioning and Adaptive Alignment

During frame welding, thermal stress causes unavoidable deformation, often leading to hole position tolerances of ±0.5 mm. Traditional mechanical limiters lack flexibility, increasing the risk of sleeve misalignment that can affect chassis accuracy.

To address this, XIRO’s vision-guided press machine employs industrial cameras to capture the position of both the frame holes and sleeves (accuracy ±0.05 mm). Using sub-pixel edge detection, the system calculates compensation coordinates as follows:

Translation compensation: ΔX = Δx · cosθ − Δy · sinθ

Rotation compensation: ΔY = Δx · sinθ + Δy · cosθ

This technology enhances angular correction accuracy to ±0.1°, a fivefold improvement over traditional methods.

Additionally, a force-controlled adaptive alignment algorithm is activated during the initial pressing phase. The servo press senses real-time contact reaction forces (threshold ≈ 200 N) and micro-adjusts its X/Y orientation, achieving flexible alignment that prevents surface scratches and misfits.

In a recent case study, an automaker adopting this system reduced rework due to positioning errors from 3.2% to 0.05%.

2. Precision Servo Pressing Execution

Frame sleeve pressing requires both structural strength and positional precision. Traditional hydraulic systems often produce pressure overshoot due to delayed response (with scrap rates up to 5%). The XIRO electric servo press offers high-precision pressure control (±0.5% F.S.) and displacement control (±0.001 mm), enabling fully controlled pressing curves.

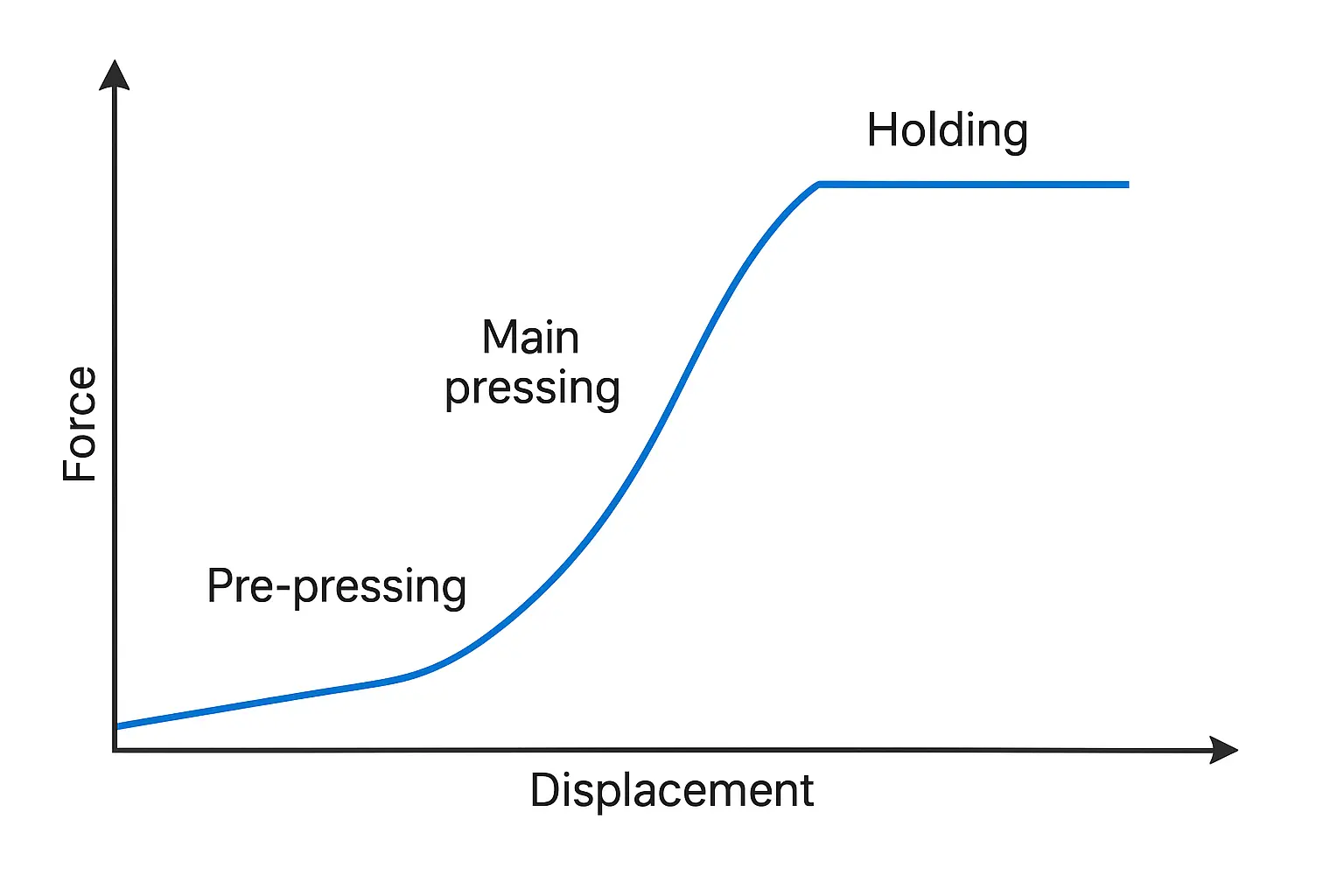

(1) Multi-Stage Pressing Curve

The system features a servo motor driving a precision ball screw (efficiency >90%), with closed-loop feedback from force and displacement sensors. The process is divided into distinct stages:

Pre-pressing stage (5kN, 50mm/s): Rapid elimination of sleeve-hole clearance.

Main pressing stage (25kN, 5mm/s): Accurate interference fit of 0.05 mm.

Holding stage (15kN, 10s): Suppression of elastic rebound (<0.03 mm).

These parameters are typical for aluminum alloy frames. For steel frames, the system automatically switches to the corresponding process recipe (e.g., 35 kN main press force, 0.03 mm interference) to prevent cracking.

The system also supports multi-sleeve vertical pressing and automatic flipping, with robotic handling transferring the frame to the next workstation, ensuring consistent cycle efficiency.

(2) Process Programming and Smooth Motion Control

Users can define multiple process stages, specifying target speeds and trigger conditions (e.g., reaching specific force or position). Through the HMI interface, the press machine can seamlessly switch between position-control and force-control modes, achieving smooth, stable operation.

An S-curve acceleration/deceleration algorithm minimizes inertia shock, protecting both workpiece and machine structure.

Process recipes can be stored and recalled with one click, allowing fast changeovers (<2 minutes) for different sleeve materials or sizes.

Force–Displacement Control Profile

(Source: XIRO )

3. Real-Time Quality Monitoring

(1) SPC Envelope Judgment

The system automatically generates a force–displacement curve during each cycle. By referencing an SPC-based envelope range derived from qualified samples, it compares the live pressing curve in real time and triggers an alarm when deviations occur.

(2) Intelligent Defect Detection

The system defines multiple quality thresholds, including:

Peak force deviation: ±5%

Displacement deviation: ±0.02 mm

Abnormal slope rate detection

When anomalies are detected, the system automatically outputs an NG signal, directing the robot to transfer the defective part to a quarantine area. Each rejected part is tagged with a unique traceability code, and the production line pauses until operator confirmation.

Typical defect patterns include:

Overpressure damage: Steep force spike during pressing or holding; caused by hard debris or undersized holes.

Case: A manufacturer observed >30% peak force spikes caused by welding spatter inside holes.Poor fit: Abnormally low pressure plateau (<22 kN); due to undersized sleeve or oversized hole.

Surface scratching: High-frequency low-amplitude oscillation (<0.5>10 Hz); often caused by surface roughness (Ra >1.6 μm), inadequate lubrication, or hard-particle embedding when pressing steel sleeves into aluminum frames.

4. Data Traceability and Process Optimization

The press machine integrates force sensors, displacement feedback, and full-cycle data recording, capturing complete pressure–displacement–time curves along with key parameters (peak force, final force, final displacement, cycle time, stage speeds, trigger points, etc.).

All data are uploaded automatically to the MES system, generating a unique traceability ID for every part. Engineers can review individual curves to pinpoint anomalies such as abnormal peaks or displacement deviations.

A built-in data analytics module applies trend-based optimization—if average peak force across a batch rises above tolerance, the system automatically recommends adjustments to pressing speed or lubrication parameters, achieving closed-loop process optimization.

Automotive Frame Sleeve Assembly (Source: XIRO )

Conclusion

By integrating visual guidance, adaptive alignment, servo-driven precision control, and full data traceability, XIRO’s automated servo press solution effectively resolves the long-standing challenges of positioning deviation, overpressure damage, and inconsistent assembly in traditional hydraulic pressing processes.

Verified in multiple automotive OEM production lines, this intelligent press machine has reduced rework rates to below 0.1%, increased line productivity by over 25%, and achieved 100% traceable pressing data—providing a benchmark solution for intelligent chassis assembly and high-precision automotive manufacturing.