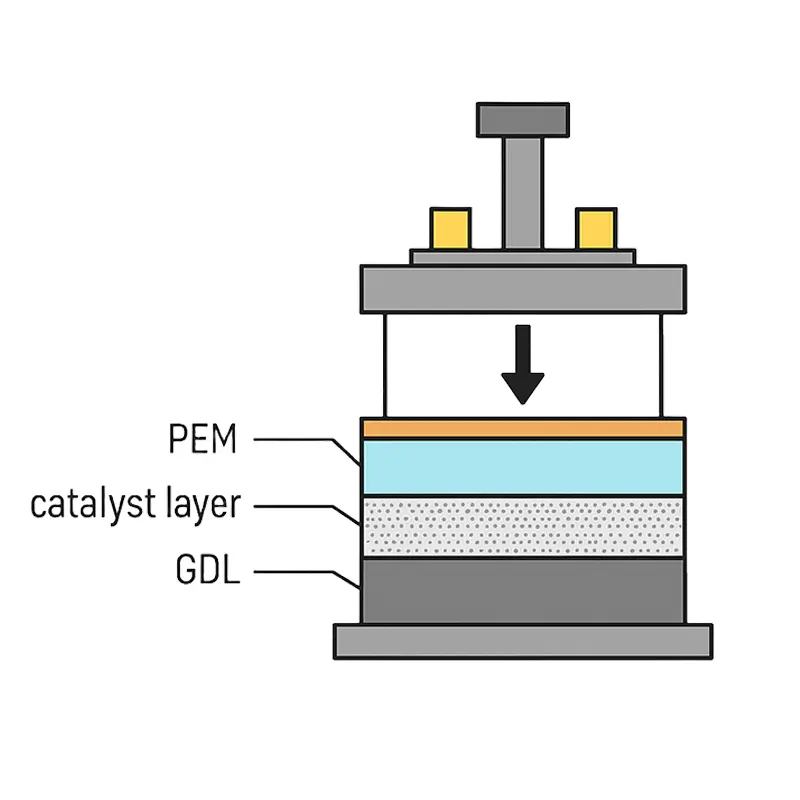

The membrane electrode assembly (MEA) is the core component of hydrogen fuel cells, and its manufacturing quality directly determines the cell’s output performance, durability, and cost competitiveness. As the key step that defines the bonding quality between the catalyst layer, proton exchange membrane (PEM), and gas diffusion layer (GDL), the hot-pressing process places extremely high demands on pressure accuracy, temperature control, and long-term stability.

However, due to ultra-thin materials, fragile mechanical properties, and a very narrow thermal-processing window, MEA hot-pressing has become one of the most challenging bottlenecks in hydrogen energy industrialization.

Hydrogen Fuel Cell MEA Manufacturing

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

Combining high-precision force control, programmable pressure curves, flexible initial contact control, and full-process data traceability, XIRO servo press machine provides a breakthrough hot-pressing solution for MEA manufacturers. This article systematically analyzes the technical challenges of MEA hot-pressing and presents how the servo press machine addresses these pain points.

Ⅰ.Six Major Challenges in MEA Hot-Pressing

1. Damage-Free Handling of Ultra-Thin and Fragile Materials

The PEM is only 10–20 μm thick, the catalyst layer is a nanostructured porous material, the GDL is mechanically fragile, and the sealing frame is made of soft polymer. These properties result in extremely high sensitivity during hot-pressing.

Typical risks include:

Initial contact shock causing PEM puncture

Catalyst layer pore collapse or powder loss

Localized damage or delamination of the GDL

A precision-controlled press machine is essential to prevent mechanical damage.

2. Extremely Tight Thermo-Mechanical Coupling Requirements

The PEM hot-pressing window is typically:

130–150°C

0.5–2 MPa pressure

Dozens of seconds to several minutes

To achieve PEM softening (not melting) and molecular interpenetration between the ionomer, catalyst and PEM chains, the temperature and pressure must be tightly coordinated.

Common issues include:

Excessive temperature → PEM melting & reduced proton conductivity

Insufficient temperature → Higher interfacial resistance

Excessive pressure → Catalyst layer pore compression & impaired gas transport

Insufficient pressure → Poor interfacial bonding

These characteristics make MEA production highly dependent on precise servo-controlled hot-pressing equipment.

3. Alignment Difficulty & Thermal Expansion Mismatch Across Multiple Layers

MEA/CCM assembly typically requires precise stacking of 5–7 layers (release film, PEM, catalyst layer, GDL, sealing frame), with an alignment accuracy requirement of ≤0.1 mm.

Thermal expansion mismatch is a major challenge:

PEM expansion coefficient: extremely high

GDL expansion: much lower

Difference between the two can reach 20×

With a 100°C temperature rise, materials can exhibit 0.1–0.2 mm differential expansion, leading to:

Misalignment

Frame welding offset

GDL intrusion into PEM regions

Real-time compensation is crucial for consistent MEA quality.

4. High Requirements for Pressure-Holding Stability

MEA hot-pressing typically requires stable pressure for tens of seconds to several minutes, with a strict stability requirement of < ±1%.

Traditional hydraulic presses face issues:

Oil temperature drift causing pressure fluctuation

Slow response, unable to compensate in time

Poor long-term pressure stability

A servo press machine provides closed-loop force control significantly better suited for this application.

5. Full Process Traceability Requirements

MEA performance is highly sensitive to:

Pressure ramp rate (affects layer slippage)

Temperature uniformity

Micro-scale displacement changes

Real-time pressure compensation

Complete capture of pressure–time, temperature–time, and displacement–time curves is essential.

For modern MEA manufacturing, high-frequency sampling ≥100 Hz is required (far above the 10 Hz capability of conventional systems).

6. Stringent Cleanliness and Anti-Contamination Requirements

PEM is highly sensitive to metal-ion contamination (>5 ppm can cause failure).

GDL and catalyst layers readily absorb oil mist, particles, or volatile residues.

Hot-pressing equipment must avoid:

Metal ion contamination

Oil contamination (common in hydraulic systems)

Particulate and chemical residues

Heating plate material corrosion

A clean, oil-free press machine is mandatory in MEA production.

Ⅱ. XIRO Servo Press Machine Solutions for MEA Hot-Pressing

1. High-Precision Force Control System

Multi-stage soft-press initialization

Ultra-low initial force ≤0.1 MPa prevents PEM and catalyst layer damage.

High-precision parallelism

Press plate parallelism reaches ≤0.02 mm/m², ensuring uniform force distribution.

High-resolution displacement control

Servo motion accuracy reaches ±0.01 mm, ensuring smooth press-plate engagement without impact.

Programmable pressure curves

Supports S-curve, exponential, and stepwise pressing modes to reduce internal stress and optimize bonding.

2. Temperature–Pressure Coordination System

±1°C heating uniformity

Ensures consistent temperature across the active MEA area.

Intelligent temperature–pressure matching

Precise control to ensure PEM softening, ionomer flow, catalyst integration, and frame bonding activation.

Three-stage thermal management:

Heating stage: prevents premature material sliding

Holding stage: ensures molecular-chain interpenetration

Cooling stage: minimizes internal stress and delamination risk

XIRO Servo Press Machine for MEA Hot-Pressing (Customizable )

3. Visual Alignment & Thermal Expansion Compensation

High-resolution CCD vision alignment (≤50 μm)

Ensures accurate initial stacking of PEM, CCM, GDL, and sealing frames.

Pre-press fixation

Low-force pre-press stabilizes all layers, preventing slippage during high-pressure hot-pressing.

Thermal expansion compensation algorithm

Real-time correction based on CTE values and temperature rise to ensure perfect layer alignment.

4. Stable Pressure-Holding & Energy Efficiency

Full closed-loop servo force control (< ±0.5% deviation)

Ensures stable hot-pressing even during long cycles.

Zonal heating + liquid cooling

Reduces energy consumption and maintains thermal stability.

High-rigidity frame (< 0.005 mm deformation)

Ensures no structural relaxation during pressure holding.

5. Complete Data Traceability

100+ process-recipes storage

Supports fast changeover for multiple MEA types.

Real-time data recording

Pressure/time, temperature/time, displacement/time curves automatically stored.

Built-in SPC analysis

Predicts GDL compression behavior, catalyst densification trends, and process drift.

6. Cleanroom-Compatible Structural Design

Fully electric drive, oil-free

Sealed pressing chamber to prevent particle intrusion

Heating plate built with corrosion-resistant materials (e.g., 316L stainless steel)

Designed for long-term stable operation in high-cleanliness fuel cell production lines.

Ⅲ. Conclusion

XIRO servo press machine provides a highly reliable, high-precision solution for MEA hot-pressing—addressing critical industry challenges such as pressure stability, thermal management, layer alignment, and contamination control.

Compared with traditional hydraulic presses, the servo press machine offers:

Higher consistency

Better repeatability

Complete process traceability

Cleaner, more intelligent operation

As the hydrogen energy industry moves towards higher performance and lower cost, servo press machines will become the mainstream equipment choice for large-scale MEA manufacturing. XIRO's advanced hot-pressing technology empowers manufacturers to achieve higher-quality MEA production with stronger process control, improved yield rates, and superior long-term reliability.