Electromagnetic coil assembly typically involves coil insertion, housing press-fit, fastening components (such as bolts or snap-fit parts), and magnetic core or iron core pressing. Due to the delicate structure of coils, the sensitivity of enamel wire insulation, and the widespread use of nylon-based plastic bobbins, the press-fit process imposes extremely high requirements on stability, speed control, pressure accuracy, and coaxial alignment.

Based on proven industrial press-fit mechanisms and extensive engineering experience, this article systematically analyzes the key failure modes encountered in electromagnetic coil assembly. It further presents a practical and production-ready solution using XIRO electric servo press machine, enabling precise press-fit control, real-time force–displacement monitoring, and full process traceability.

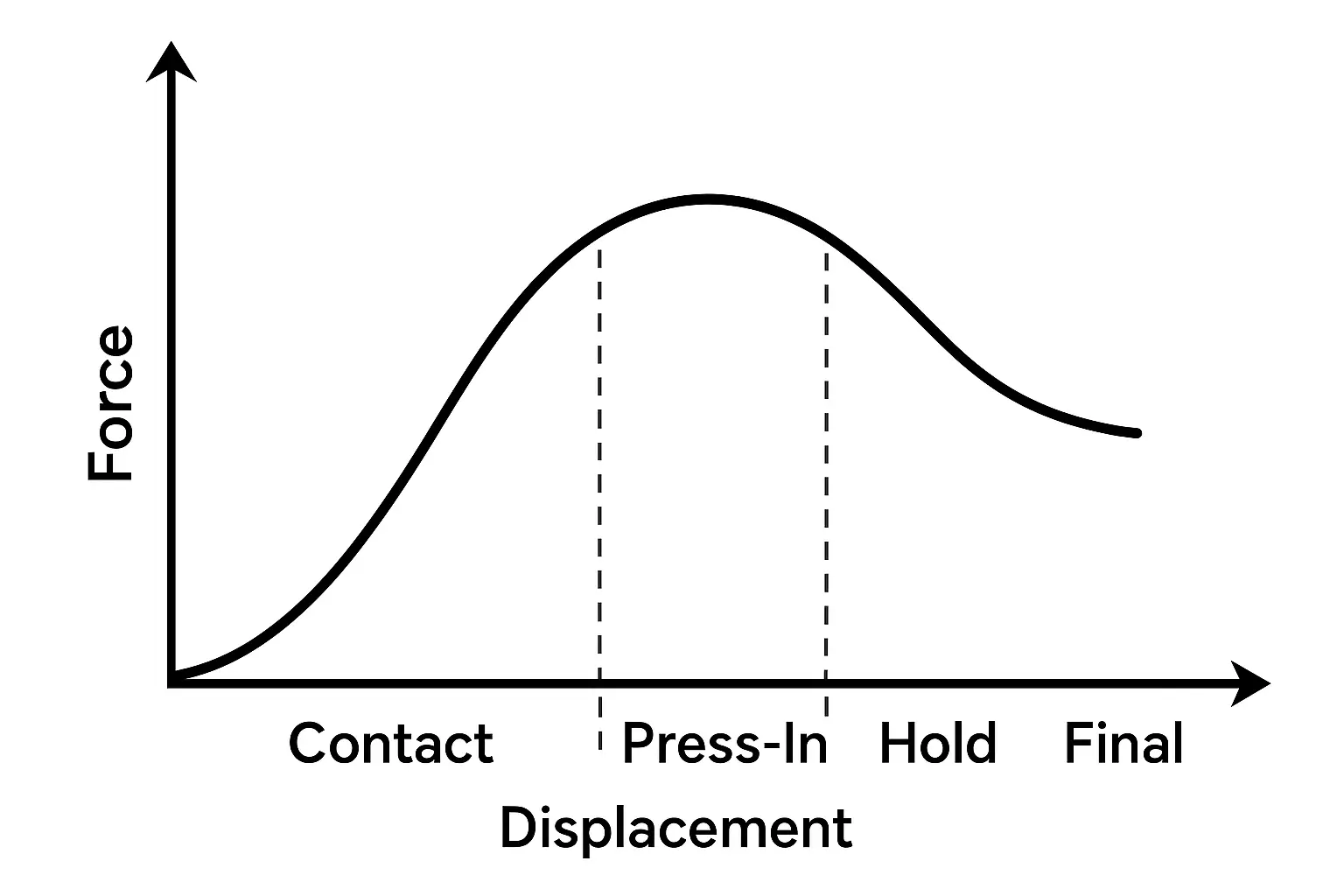

Press-fit Force–Displacement Curve

(Source: XIRO )

1. Key Challenges and Failure Mechanisms in Electromagnetic Coil Assembly Press-Fit

1.1 Enamel Wire Insulation Damage and Inter-Turn Short Circuit

Root Causes:

Excessive initial contact speed causing impact force to concentrate on the coil end.

Micro-tilt between the press head and the workpiece, resulting in edge scratching of enamel wires.

Conventional pneumatic or hydraulic press machines lack continuous pressure control, leading to transient pressure overshoot.

Case Study: When a relay coil was assembled using a pneumatic press machine, the cylinder descended at a speed of 15 mm/s. The iron core contacted the bobbin at an angle, causing localized impact. The enamel wire insulation cracked, leading to an inter-turn short circuit and immediate burnout after energization.

1.2 Bobbin or Magnetic Core Cracking

Root Causes:

Press-fit force exceeding material limits or absence of deceleration stages.

Poor chamfer quality on magnetic cores, resulting in localized stress concentration.

Assembly misalignment causing unilateral loading.

Case Study: During the press-fit of a micro motor stator coil, variations in magnetic core chamfer dimensions (±0.05 mm tolerance) caused excessive edge stress, leading to micro-cracks and abnormal operational noise.

1.3 Coil Deformation and Internal Structure Displacement

Root Causes:

Press-in speed too high, preventing a smooth force ramp-up.

Uneven bobbin wall thickness causing copper wire displacement.

Fixture positioning errors amplifying lateral stress.

Case Study: In small relay assembly, high downward speed (15 mm/s) caused instantaneous impact when the core was inserted, deforming the bobbin sidewall and forcing copper wires to stack unevenly. In some cases, slight initial angular misalignment caused unilateral loading, twisting the bobbin and damaging wire insulation.

1.4 Accumulated Micro-Damage Due to Stress Relaxation

Root Cause: Common glass-fiber-reinforced nylon materials such as PA66+GF30 exhibit rapid stress relaxation within 2–5 seconds. Without a dwell or holding phase, elastic recovery after unloading can reach 3–8 μm, potentially leading to long-term loosening.

Case Study: In fuel injector coil assembly, the absence of a holding stage caused immediate unloading after reaching position. The bobbin elastically recovered, forming a micro-gap that compromised long-term stability.

1.5 Hidden Damage Caused by Material Defects

Root Causes:

Nylon injection debris (≤0.2 mm) crushed during press-fit, generating transient impact forces.

Micro-burrs on magnetic cores (Ra ≈ 3.2 μm) scratching enamel insulation.

Lack of initial contact force detection prevents early defect identification.

Case Study: In wheel speed sensor coil assembly, residual nylon debris and core burrs caused enamel damage during impact pressing. Due to the absence of initial force monitoring, the defect detection rate was below 20%.

1.6 Inaccurate Press-Fit Depth or Position Deviation

Root Causes:

Poor repeatability of conventional press machines.

Mechanical backlash and cumulative positioning errors.

Lack of force–displacement curve evaluation and real-time alignment compensation.

Case Study: Automotive solenoid coils require a press-fit height tolerance of ±0.05 mm. Traditional hydraulic press machines with ±0.1 mm repeatability caused inconsistent valve stroke and unstable flow control.

2. XIRO Electric Servo Press Machine Solution

To achieve high-precision electromagnetic coil assembly, the XIRO electric servo press machine integrates high-accuracy position control, millisecond-level force response, programmable press-fit profiles, and full process data traceability. This integrated approach effectively controls transient impact, localized stress concentration, material rebound, and fixture-induced errors within quantifiable safety margins—while maintaining production efficiency.

2.1 Three-Level Closed-Loop Control Architecture

By coordinating a servo motor, high-response force sensor, and real-time PID control algorithms, the system ensures smooth, impact-free press-fit execution and protects enamel wire insulation throughout the process.

Servo Drive Layer:

A high-dynamic servo motor combined with a planetary gearbox achieves positioning accuracy of 0.01 mm and dynamic response within 10 ms. Encoder feedback ensures the press head follows the programmed trajectory precisely.

High-Resolution Force Sensing Layer:

Integrated force sensors with a 1 kHz sampling rate and 24-bit A/D conversion capture millisecond-level force fluctuations, including subtle variations caused by wire scratching or micro-defects.

Control Algorithm Layer:

Pressure overshoot suppression by reducing proportional gain near target force.

Force fluctuation damping via derivative prediction, limiting variations within ±0.5% F.S.

Feedforward compensation to ensure material variations do not disturb the force–displacement curve.

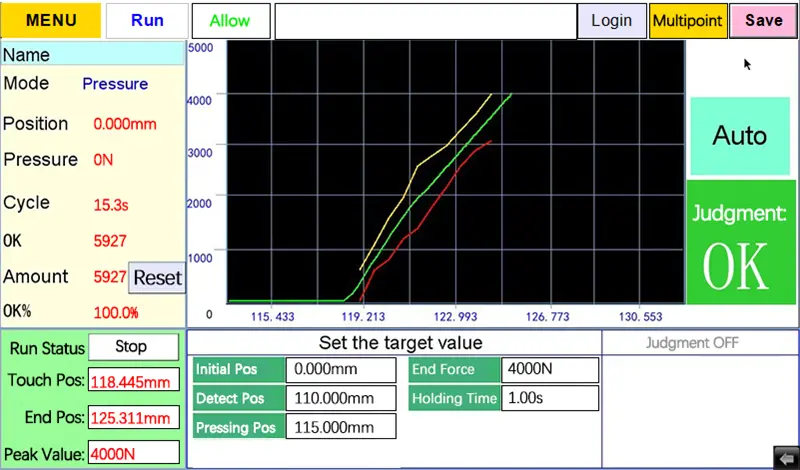

2.2 Force Limit Protection and Curve Window Monitoring

Maximum Force Limit:

An absolute force threshold (e.g., 2 kN) is set to immediately stop the press machine upon overload.

Curve Window Monitoring:

A qualified force–displacement curve window is established:

Early force rise before reaching target position indicates burr jamming or foreign debris.

Abnormal slope changes suggest bobbin wall thickness variation or copper wire obstruction.

Coaxial Alignment Control:

Through the combination of a servo press machine and precision fixtures, press head-to-workpiece coaxial deviation is maintained within ≤0.02 mm.

2.3 Multi-Stage Speed Control

To protect enamel wire, bobbins, and copper wire stacking structures, the press-fit process is divided into three stages:

Dectation Stage: 1–3 mm/s with contact detection at 0.1 kN to identify the coil top reference point.

Press-in Stage: 0.5–2 mm/s for stable copper wire deformation and uniform load distribution.

hold Stage: 0.1–0.5 mm/s near target position to prevent stress concentration at the bobbin end.

XIRO Electric Servo Press Force-Position Curve Monitoring Interface

2.4 Interference Fit Control and Stress Relaxation Compensation

Force–Displacement Analysis:

Peak force, final position, and curve slope from multiple qualified samples are used to calculate the actual interference fit and optimize process parameters.

Holding Function:

By maintaining force or position for 2–5 seconds, micro-creep of the bobbin material fills surface irregularities. Elastic rebound is reduced to ≤1 μm, preventing long-term loosening or micro-cracking.

2.5 Full Process Data Monitoring and Defect Diagnosis

| Defect Type | Force–Displacement Feature | Physical Meaning |

| Bobbin debris | Initial spike + sudden drop | Debris crushed |

| Core burrs | Periodic mid-stage oscillation | Enamel scratching |

| Wire bending | Displacement stagnation plateau | Wire obstruction |

| Material aging | >10% force decay during hold | Bobbin degradation |

Practical Case:

In a batch with high copper wire deformation:

80% of abnormal curves showed a “double-peak” pattern caused by initial wire collapse followed by secondary impact due to excessive speed. Reducing press-in speed from 2 mm/s to 1 mm/s resolved the issue.

20% showed abnormal initial slope caused by worn fixture locating pins, fully corrected after replacement.

Conclusion

By combining high-precision position control, millisecond-level force closed-loop regulation, adaptive multi-stage speed profiles, interference fit optimization, and stress relaxation compensation, XIRO electric servo press machine effectively addresses the most common failure modes in electromagnetic coil assembly press-fit processes.

With real-time force–displacement curve monitoring and full data traceability, manufacturers can rapidly diagnose issues related to materials, structure, fixtures, and equipment conditions—significantly improving yield, consistency, and long-term reliability in high-precision industrial assembly applications.