The transmission gear shaft is a critical component of an engine powertrain system. Its press-fitting quality directly impacts the overall transmission efficiency, system reliability, and service life of the vehicle. Traditional press-fitting processes face numerous limitations in terms of precision and control—especially when dealing with complex interference fits, micron-level coaxiality, and fatigue resistance. This article analyzes key challenges in gear shaft assembly through real-world cases and presents high-performance technical solutions based on XIRO electric servo press systems.

Transmission Gear input shaft

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

Challenge 1: Unstable Pressing Force Leading to Bearing Damage

Case: A transmission manufacturer experienced high defect rates when press-fitting deep groove ball bearings into input shafts using a traditional hydraulic press. Due to the low control accuracy of proportional valves in the hydraulic system, instantaneous peak pressures frequently exceeded design thresholds. Monitoring data revealed peak pressure fluctuations ranging from 18 to 32 kN, causing localized plastic deformation of the bearing raceways. The monthly rejection rate reached 5.3%.

XIRO Electric Servo Press Solution

By integrating a high-response servo motor (response time < 5 ms) with a ball screw direct-drive mechanism, combined with a high-precision pressure sensor (±0.5% FS), the system achieves real-time closed-loop control:

Pre-pressing Stage: Ramped force application at 5 kN/s up to 15 kN to eliminate assembly clearance.

Main Pressing Stage: PID algorithm dynamically compensates load variations to maintain 24.5 ± 0.3 kN constant pressure.

Dwell Stage: Constant pressure maintained for 2 seconds to ensure proper interference engagement.

Results: Peak pressure fluctuation reduced to within ±1.2%, bearing rejection rate dropped to 0.3%. For an annual production volume of 300,000 units, this equates to annual savings of approximately ¥2.87 million.

Challenge 2: Substandard Coaxiality in Complex Stepped Shaft Assembly

Case: A German automotive OEM faced difficulty during press-fitting of a planetary gear stepped shaft (Φ28–Φ35–Φ42) using a pneumatic press. The system’s low rigidity (air's equivalent modulus ≈ 0.7 MPa) and off-center pressing forces caused the press head to tilt. Additionally, fixture positioning errors compounded to 0.08 mm, making it nearly impossible to control housing bore coaxiality within the 0.03 mm specification.

XIRO Electric Servo Press Solution

A high-rigidity linear guide system (±0.005 mm repeatability) was integrated with a 6-axis force sensor (torque resolution 0.1 N·m) for real-time off-center force detection, enabling segmented press-fitting:

Positioning Stage: Low-speed insertion at 0.5 mm/s with real-time axial deviation correction.

Acceleration Stage: Speed increased to 3 mm/s to enhance efficiency.

Results: Coaxiality compliance rate increased to 99.6%, while individual press-fit cycle time was reduced from 25 seconds to 20.5 seconds—an 18% improvement in efficiency.

Challenge 3: Surface Scratching in Interference Fits Leading to Fatigue Failure

Case: A commercial vehicle transmission factory encountered severe surface scratching (depth >15 µm) during the press-fitting of output shafts made from 20CrMnTi. The excessive impact and friction during interference fit significantly reduced fatigue life—by up to 37%, according to bench tests.

XIRO Electric Servo Press Solution

By analyzing real-time force-displacement curves, a multi-stage press-fitting strategy was implemented:

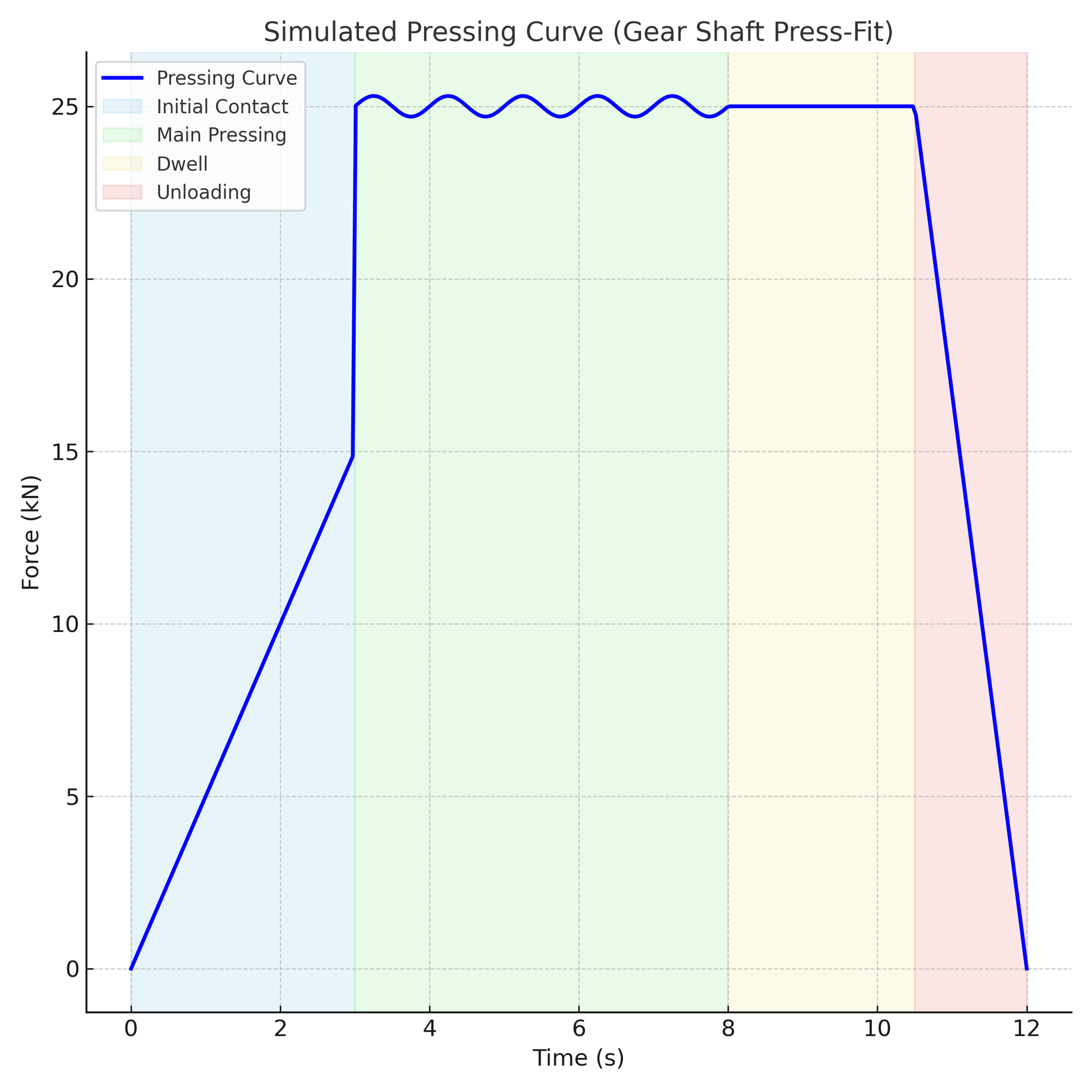

1. Initial Contact Stage

Pressing begins at a low speed of 0.2 mm/s, with force rising linearly to the preset pre-load value (e.g., 15 kN), ensuring a smooth and coaxial transitional fit.

Key Control Points:

· Maintain a smooth and uniform pressure ramp-up to avoid sudden force spikes

· The force-displacement curve in this phase should exhibit low stiffness with a linear slope

2. Main Pressing Stage

The pressing force is maintained at a constant value (e.g., 25 ± 0.3 kN), with force fluctuations strictly controlled within ±0.5% F.S., ensuring consistent interference fit quality.

Key Control Points:

· Ensure tight interference fit by sustaining force within tolerance range

· Maintain torque transmission stability, avoiding axial misalignment or side loading

3. Dwell & Unloading Stage

After reaching the target pressing force, a dwell time of 0.5 seconds is applied to stabilize the assembly. The press then unloads gradually to prevent elastic rebound or surface damage.

Key Control Points:

· Ensure complete plastic deformation of the interference fit

· Avoid rapid force release to prevent rebound-related inner wall scratches or misalignments

Simulated Pressure-Time Curve of a Transmission Gear Shaft

(Data source: XIRO)

Results:Surface scratch depth reduced to below 5 µm, and fatigue life restored to 102% of the original design target.

Key Technical Advantages of XIRO Electric Servo Presses

1. Precision Motion Control

Ground ball screws and high-rigidity linear guides ensure repeatability of ±0.005 mm.

Continuously adjustable press-fit speeds from 0.1 to 50 mm/s accommodate various materials and interference levels.

Force-displacement sampling rate up to 10 kHz allows real-time evaluation and judgment.

2. Intelligent Process Management

Integrated 1 kHz data acquisition module records 1,000 sets of process parameters per press-fit curve.

Compatible with MES systems via OPC UA protocol, capable of storing 100,000 complete press-fit curves.

Built-in SPC analysis module calculates CPK values and generates control charts. Anomalies are detected in under 3 seconds.

3. Energy Efficiency

Standby power consumption is less than 0.5 kW (vs. ≥15 kW for traditional hydraulic systems), resulting in over 80% energy savings.

Oil-free design extends service life of critical components.

Item | Traditional presses

| XIRO | Benefit |

Energy Consumption per Unit | 1.8 Kw·h | 0.6k W·h | 80% Energy Savings |

Pressure Response Speed | >50 ms | <10 ms | 5× Faster Pressure Response Speed |

Mean Time Between Failures | 8000 h | 25000 h | 3× Longer Mean Time Between Failures |

Noise Level | 75-85Db(A) | <65 dB(A) | 30% Noise Reduction |

Conclusion

In summary, challenges such as unstable force control, misalignment in coaxiality, and surface damage from interference fits continue to impact transmission gear shaft assembly quality and reliability. XIRO electric servo presses have demonstrated proven success across numerous automotive applications, thanks to their precise control, rapid dynamic response, and advanced intelligent process management.

Discover how XIRO Electric servo press technology can help your production line reduce scrap, accelerate changeovers, and improve traceability. Contact us or visit YouTube channel to explore 100+ servo press applications demos across the automotive, aerospace, and precision manufacturing sectors.